Fairfield County, South Carolina, is typical of many rural counties in America. Located between Columbia, South Carolina, and Charlotte, North Carolina, the county has an area of 700 square miles and a population of 24,000. Budgets are tight, and the maintenance of approximately 220 miles of unpaved (gravel surfaced) county roads is an ongoing problem. Although the unpaved roads have low-volume traffic, maintenance requires frequent blading of the gravel, and the surface aggregate has to be replenished on a regular basis (costing the county about $200,000 per year). In addition, the citizens are faced with lower quality roadways, with dust and other associated problems of unpaved surfaces.

Dennis Corporation, an engineering consulting firm based in Columbia, South Carolina, was looking for a solution to help Fairfield County’s Transportation Committee upgrade the road conditions in a cost-conscious manner. They suggested full-depth reclamation (FDR) using cement as a means of rehabilitating failed asphalt pavements. The South Carolina DOT (SCDOT) has been using full-depth reclamation with cement for more than 10 years with excellent results, and the Dennis Corporation thought the same procedure could be used on the county’s gravel roads.

Their plan was to upgrade the gravel roads to a bituminous surface treatment (chip seal), which would provide a smoother, safer road surface and eliminate the problems with dust and the expensive maintenance of blading and gravel replacement. The FDR process on the gravel road would make use of the existing gravel by blending it with cement and subgrade materials to a depth of 6 inches. This cement-stabilized material would make an excellent base for a triple bituminous surface treatment (or a thin asphalt surface).

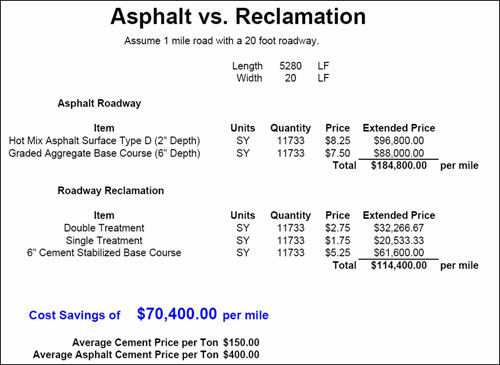

The cost evaluation showed that the FDR process, with the surface treatments, would save the county over $70,000 dollars per mile compared to the alternative of a standard asphalt pavement with a 2 inch surface and 6 inch aggregate base (see table below). This cost savings would allow the county to upgrade three miles of road using the full-depth reclamation with cement process for every two miles of asphalt pavement that could be constructed at the same cost.

Cost comparison of asphalt vs. reclamation

In September of 2006, the county contracted with Site Prep Inc., Monroe, North Carolina, to perform the upgrading of 14 sections of unpaved road in different locations around the county (totaling 13.5 miles). The design called for 33 pounds of cement per square yard of roadway, mixed and compacted to a depth of 6 inches. The full-depth reclamation process would also allow the road template to be improved by establishing road crown and shoulders, which would improve drainage and road safety.

Construction was completed at the rate of 1,500 – 2,000 feet per day, with a single treatment of chip seal applied the same day (to provide protection for the new base, and a better surface for residents to travel on during construction). After completion of each section a double chip seal was applied to complete the triple surface treatment.

Mixing cement during the FDR process

Improving the road template

Application of bituminous surface treatment (chip seal)

The county was extremely pleased with the final product, especially considering that the cost savings allowed more miles of roadway to be improved. Dennis Corporation President, Dan Dennis, PE, stated “…we were able to save the taxpayers approximately $1.5 million and improve their quality of life by paving existing dirt roads that many citizens had driven on their entire lives”.

The fact that the road base is cement stabilized will improve the long-term performance of the reconstructed sections, since the higher strength base can carry heavier loads and is much less susceptible to water damage than stone base. The county was so impressed by the process that they are planning to upgrade 16 more miles in their roadway improvement program for 2007. By making improvements each year, it won’t take long for the county to substantially increase the quality of their road system, and make excellent use of their scarce resources by stretching those construction dollars.