Hot cement describes clinker that has, through the process of grinding, gained additional energy stored in the form of heat. Once the clinker is ground, this hot cement is stockpiled in storage silos where the elevated temperature, especially in warm climates, is not readily abated.

Hot cement describes clinker that has, through the process of grinding, gained additional energy stored in the form of heat. Once the clinker is ground, this hot cement is stockpiled in storage silos where the elevated temperature, especially in warm climates, is not readily abated.

Summer months exacerbate the situation since ambient temperatures are generally high and cement consumption increases. The warmer temperatures reduce the ability of the hot cement to release large quantities of heat to the ambient air; and increased consumption means freshly ground cement is not stored very long before being shipped to the ready-mixed plants for use in batching.

Many attribute slump loss, strength reduction, or other concrete-related problems to the temperature of the cement upon batching. However, research has shown that cement’s ultimate effect on the concrete mixture’s temperature is quite minimal.

Many attribute slump loss, strength reduction, or other concrete-related problems to the temperature of the cement upon batching. However, research has shown that cement’s ultimate effect on the concrete mixture’s temperature is quite minimal.

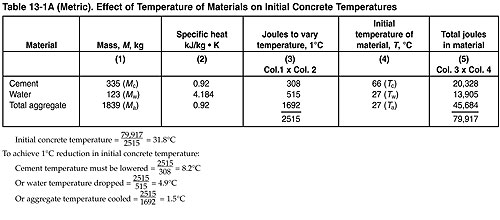

Initial studies by Lerch, 1955, (see reference below) and duplicated research has shown that to lower the temperature to normal concrete by 1 degree Celcius, the temperature of the cement must be reduced by 8.2 degrees Celcius, the temperature of the water reduced by 4.9 degrees Celcius, and the temperature of the aggregates lowered only 1.5 degrees Celcius. Thus the influence of cement temperature on overall concrete batch temperature is less than that of the other concrete ingredients. See Table 1 below, adapted from Design and Control of Concrete Mixtures, 2002, for a representation of the effect between relative mass proportions and specific heat capacity and temperature influence on a concrete mix.

The reason for this effect can be traced to the mix proportions and the intrinsic thermal properties of the concrete ingredients. Of the materials added to normal concrete, cement occupies only seven to 15 percent of the concrete volume. Water and aggregates generally constitute approximately 70 to 90 percent of the concrete volume. When compared to the weight of the other constituents, cement’s potential influence on temperature is diminished. In addition, cement has a very low average specific heat capacity (0.92 kJ/kg•K) – meaning that it gains and loses heat very readily when exposed to high temperatures or when supplied with energy. Aggregates, on average, have an equivalent specific heat capacity to that of cement, but water’s specific heat is very high (4.184 kJ/kg•K) – meaning it can store large amounts of heat.

The reason for this effect can be traced to the mix proportions and the intrinsic thermal properties of the concrete ingredients. Of the materials added to normal concrete, cement occupies only seven to 15 percent of the concrete volume. Water and aggregates generally constitute approximately 70 to 90 percent of the concrete volume. When compared to the weight of the other constituents, cement’s potential influence on temperature is diminished. In addition, cement has a very low average specific heat capacity (0.92 kJ/kg•K) – meaning that it gains and loses heat very readily when exposed to high temperatures or when supplied with energy. Aggregates, on average, have an equivalent specific heat capacity to that of cement, but water’s specific heat is very high (4.184 kJ/kg•K) – meaning it can store large amounts of heat.

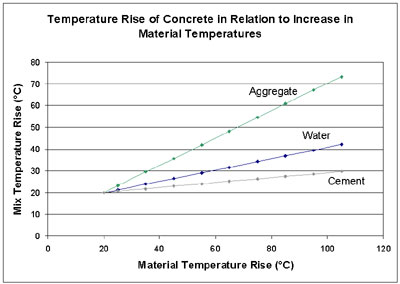

The importance of controlling concrete temperature is well understood. Temperature affects fresh and hardened properties of concrete as well as the thermal cracking potential. Careful attention must be paid to batch temperatures in hot and cold weather concreting. However, as evidenced by the graph below, the relative effect of hot cement on the batch temperature is negligible.

Note: This graph represents the relative effect of each mix constituent assuming the other temperatures are held constant at 20 degrees Celcius.

References

Kosmatka, S. H. and Wilson, M. L., Design and Control of Concrete Mixtures, EB001.15, 15th edition, Portland Cement Association, Skokie, Illinois, 2011.

Lerch, W., Hot Cement and Hot Weather Concrete Tests, Portland Cement Association, Skokie, Illinois, 1955.

Wilson M.L., and Thomas, M.D.A., Hot and Cold Weather Concreting, CD057, Portland Cement Association, Skokie, Illinois, 2005. Available in the PCA Library.